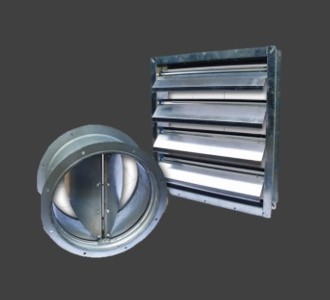

Tunnel Dampers

Description :

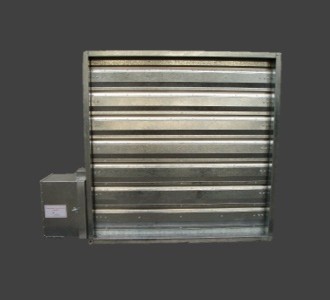

OLS Tunnel ventilation damper is constructed of standard hot-dip pre-galvanised steel frame full welded at the corner. The blade is constructed of double-skinned steel plates with stainless steel blade edge seals. Stainless steel jamb seal is installed on the vertical frame to minimise leakage between blade and frame. Damper design enables bi-directional flow. Each blade is equipped with stainless steel stub shaft and pivot on two-parts bearing. Interconnecting blade linkages are located outside the air stream and pivot on stainless steel pin. Damper may be constructed of stainless steel blade and frame. As a standard, on-off spring-return electric actuator or single acting pneumatic actuator is provided to each damper, number of actuator required depend on the torque required to meet pressure and flow requirement. The actuator is fast acting and able to close or open the damper over 90o travel in 10 seconds. Damper may be installed vertically or horizontally.

Features

- Robust and modular construction

- Double skin air foil blade withstands high torque without twisting at high pressures and velocity

- Large module size ensures high free area and lower pressure loss

- Square end/round blade stub shaft prevent slip at the actuator clamp

- Suitable for Bi-directional flow

- Quality assurance tested

- Low leakage rate less than 0.5% based on approach velocity of 10 m/s and meets UL555s requirement for Class I damper

- Temperature rating of 250°C for 2 hours

- Operating pressure to 2700 Pa

- Fast cycle time – less than 10s for electric and pneumatic operated damper