Description :

CONNOLS-AIR DDC microprocessor based V750 air terminal units are the latest, state-of-the-art, high quality terminal units, that provide good control accuracy and capabilities required in every modern intelligent building. The air terminal units are capable of stand-alone operation, however, optimum functional benefits are derived when network communication capabilities are used.

Read more

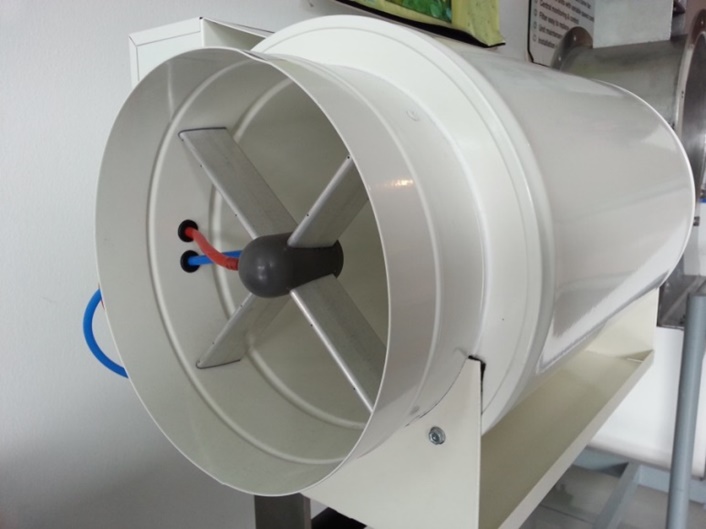

Each air terminal unit consists of an air damper with an integrated pressure differential multiple point airflow sensor, a digital thermostat and a BACnetTM compliant DDC controller. The damper is constructed of galvanized steel circular double-skin casing with 25 mm fiber glass-filled annular space. Damper blade is constructed of double-skin steel plate with solid silicon all round that provides an excellent seal when closed.

The X-Sensor (Cross sensor) is a true averaging pressure differential sensor with amplification of 2 and is able to accurately measure airflow to turndown of 2 m/s. The performance of V750 X-Sensor and damper is AMCA certified to accuracy of 3.7% or better in the velocity range of 4 to 13 m/s.

Features

- Double-skin casing construction ensures low radiated noise and prevents fiberglass erosion.

- Double-skin blade with solid silicon seal all round ensures blade rigidity and ultra low air leakage across closed damper.

- Ultra low leakage feature leads to saving in cooling and fan energy during after office hour operation.

- Blade is designed to close at 60 degrees to provide more linear flow characteristics at low flow, hence more precise control of airflow and saving in energy

- X-Sensor multi-point pressure differential airflow sensor provides accurate measurement of airflow at turndown to 2 m/s resulting in saving of energy.

- CONNOLS-AIR VAV V750 X-Sensor with its damper is AMCA certified.

- Energy saving features described above contributes to saving in carbon footprint.

- CONNOLS-AIR VAV box generate low noise at design airflow due to its airfoil X-Sensor.